- Úvod

- Home

Assembly and production lines

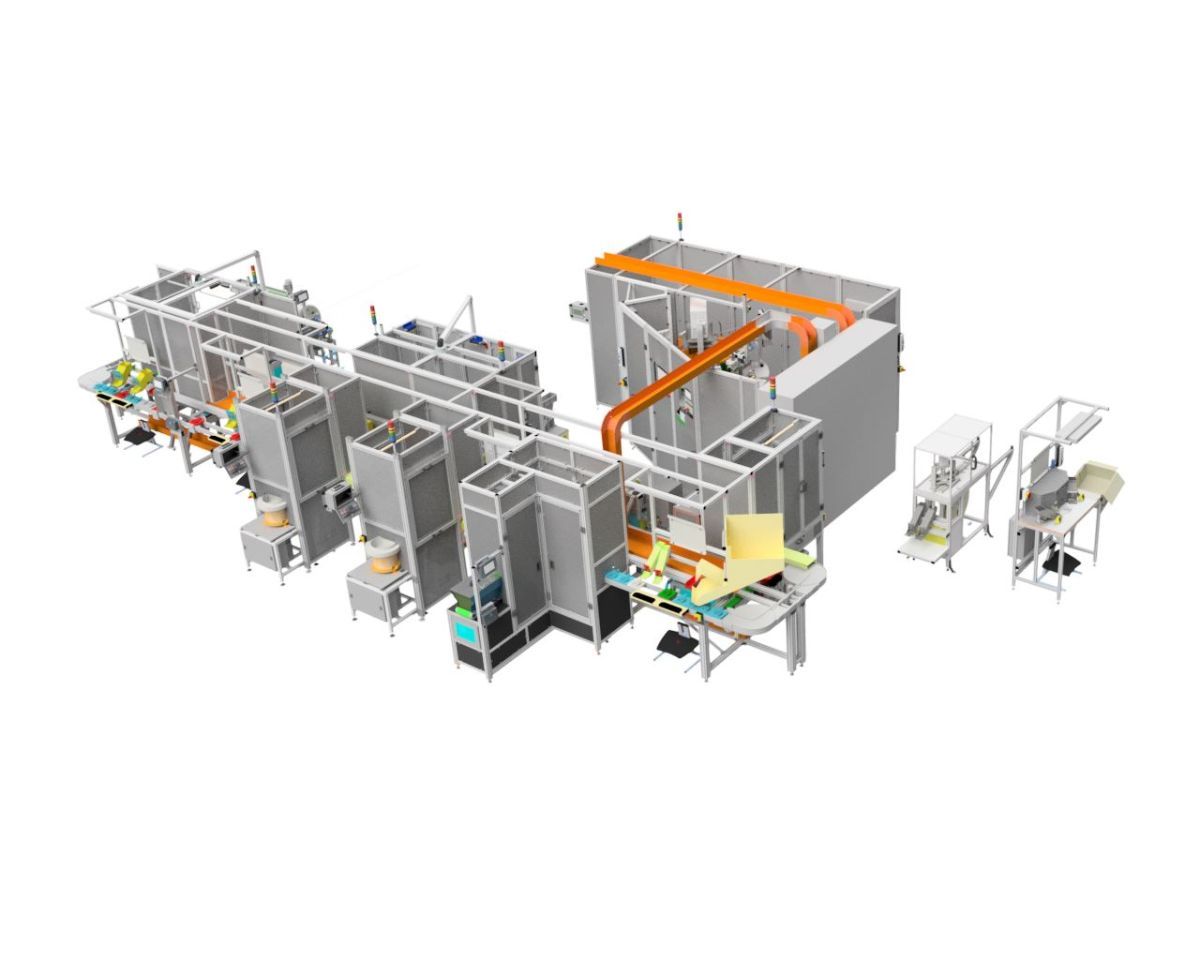

We develop and supply production and assembly lines to customers on a turnkey basis as a general contractor.

With regard to the required production volumes, technological complexity and customer requirements, it is possible to design individual operations as manual workplaces, automatic stations, or as robotic stations.

The overall degree of automation in a production line can be minimal (semi-automatic lines) to fully automated.

-

Manual workstation cycle: approx. 5 seconds or more (taking into account occupational hygiene and customer standards)

-

Automatic station clock speed: approx. 3 seconds or more

-

Degree of automation: up to 100%

-

Possibility of manual workplace integration: yes

-

Modular design possible: yes

-

Possibility of flexible design for more types of products: yes

Examples of production processes that we often apply to production lines:

-

construction

-

shaping

-

pressing

-

riveting

-

micro-resistance welding

-

soldering

-

ultrasonic welding

-

automatic control

-

product label

-

packaging

Examples of transport concept of production lines:

-

conveyor system with pallets

-

carousel rotary table

-

conveyor belt

-

sliding sliding pallets

We supply assembly lines to the following industries, for example:

-

Automotive

-

pyrotechnic industry

-

Electrotechnical industry

-

electronics industry

-

lighting industry

-

construction industry

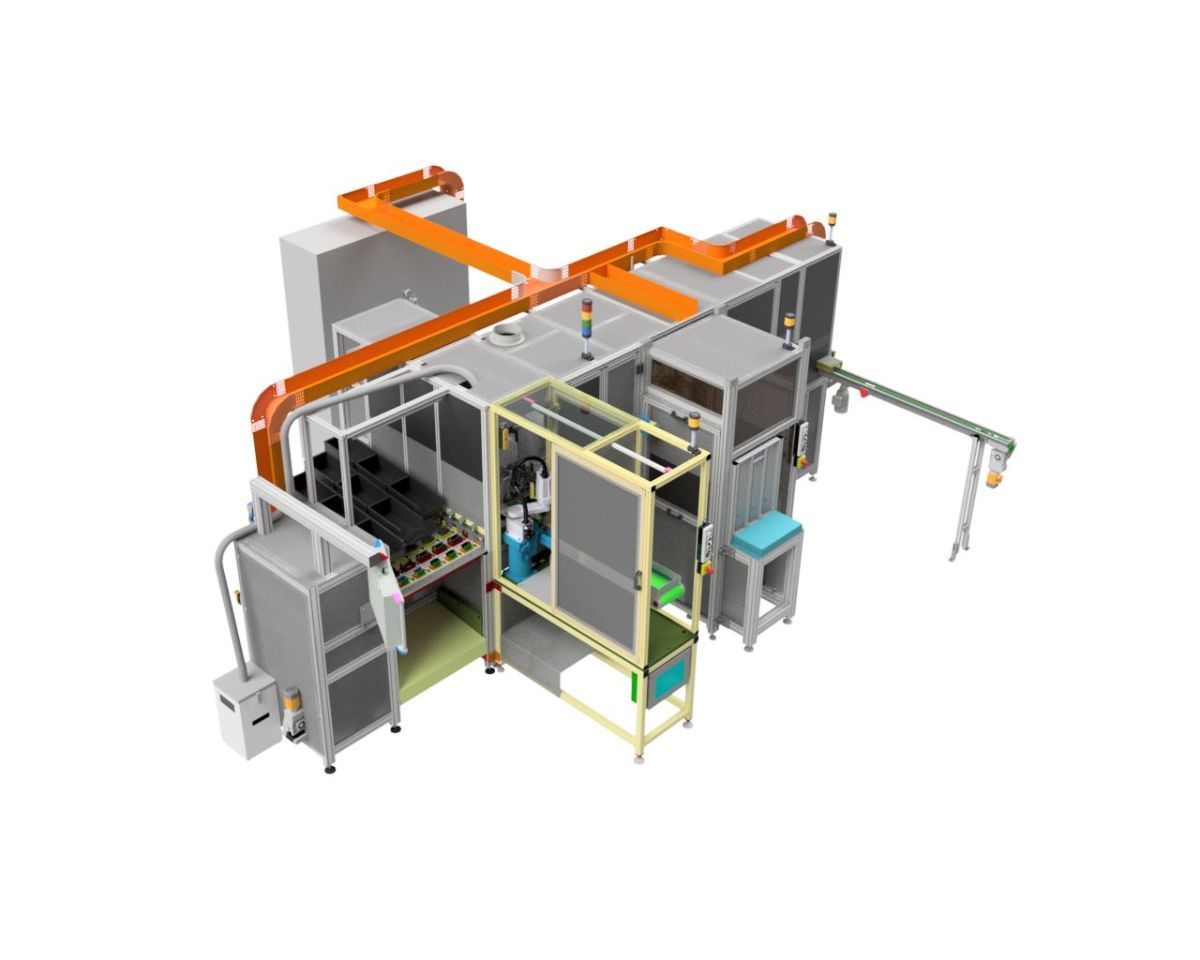

Robotized production lines

We supply robotic production and assembly lines with both industrial and collaborative robots.

Robotic arms, replacing single-purpose electromechanical and pneumatic manipulators and enable customers to obtain very flexible and productive technology with a long service life.

Advantages of robotic production lines:

-

more efficient conversion of lines to new types

-

ability to automate complex assembly processes

-

long service life

-

higher productivity and quality

-

higher probability of usability of the technology after the end of production

je registrovanou značkou společnosti TNS SERVIS s.r.o.

+420 573 034 358

TNS SERVIS s.r.o.

Divize ZLÍN ROBOTICS®

K Teplinám 619, 76315 Slušovice, Česká republika

IČO: 291 81241, DIČ: CZ291 81241

Společnost zapsána v obchodním rejstříku vedeném Krajským soudem v Brně, spisová značka C63717